ELASTICITY, ISOTROPIC,

ANISOTROPIC, HOOKEAN

Isotropic materials are those that have the same value for a given

property in all directions.Anisotropic materials are those that have

different values for a given property in different directions.

Types of deformation:Permanent, Recoverable:

Elastic response

Viscous response

Plastic response

Derived response models:

Mechanical combinations of

elastic, viscous and plastic response

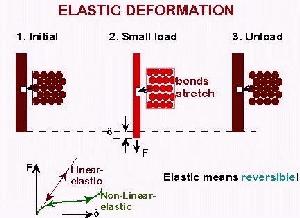

Elastic Response

Strain is recoverable instantaneously

Response to stress is instantaneous

The relationship between stress and strain is linear

For a normal stress, s

, producing an extension, e

, the relationship is given by the equation: s

= Ee

where the constant of proportionality, E, is call Young's modulus. This

equation is called is Hooke's Law

Note that E and all of the other elastic moduli described below have

the units of stress, because strain is dimensionless

Mechanical Analog for

Hookian Elastic Materials

Extension of a spring, note that:

strain-time indicates instantaneous response to stress

strain is also instantaneously recoverable

stress-strain relationship is linear

Other Elastic Responses

For dilation, the constant of proportionality is called the bulk

modulus, K, where: s

H = K (D

V/V)

For a shear stress, s

S , the constant of proportionality between shear stress and shear

strain (g)

is called the shear modulus, G, where: s

S = Gc

(The shear modulus is sometimes called the modulus of rigidity )

Poisson's ratio ( n

) is another property of an elastic material and is equal to the ratio of

lateral contraction to longitudinal extension during tensional loading

Relationships among elastic constants:

G = E/2(1+ n )

= 3K(1-2n )/2(1+n

)

Viscous Response

Newton's concept of fluid viscosity: fluid

material

Laminar flow occurs in the fluid between rigid plates as the plates

slide over one another

The fluid exerts an internal frictional resistance to the movement

which is called the viscosity of the fluid

Because of this resistance, force or shear stress must be continually

applied to keep the plate moving

For such fluids, the strain is proportional to the stress and the time

it acts, and is inversely proportional to the viscosity, h

, of the fluid

Viscous Response

The strain is proportional to the stress and the time it acts, and is

inversely proportional to the viscosity, h

, of the fluid

This relationship is given by the following equations for normal stress

and shear stress:

e = s

t/h or s

= h e

/t Þ s

= h de

/dt

similarly s s =

h dg

/dt

Note that the longer the stress is applied, the greater the strain for

a given stress.

Note that the shorter the time involved, the greater the stress

required to produce a given strain.

Viscous Response

A material that exhibits this property is said to be a Newtonian fluid

In a Newtonian fluid, the viscosity is constant for all rates of the

application of stress or rates of strain - Figure (a) below

However, there are fluids whose viscosity varies as a function of

strain rate ‑

these are called non-newtonian fluids - Figure (b) below

Most highly viscous fluids are non-newtonian

The change in viscosity as a function of strain rate is generally

attributed to structural changes within the material

It may be that non-newtonian viscous behavior is a close approximation

to that of real rocks at depth

Geological

Implications of Viscous Behavior

The slower the strain rate the lower the stress required for

deformation.

For very low strain rates (e.g. over geologic time), low stresses may

be able to deform even very viscous fluids. This has major geological

implications

Mechanical Analog of

Viscous Response

A mechanical analog for viscous behavior is the dashpot, a loose piston

moving through a cylindrical tube whose walls are lubricated by some

fluid. e.g. a hydraulic cylinder on a rowing machine. Note that:

Strain is time dependent (the longer the time, the more the strain)

(contrast this with elastic behavior)

The stress-strain rate relationship is linear

Plastic Response

An ideal plastic body does not yield until some critical stress ( s

c) is reached.

Most materials that approach being plastic exhibit elastic properties

below this point so this critical stress is at the elastic limit or yield

point of the material

Mechanical analog - a sliding mass (where s

c is analogous to frictional resistance)

Plastic Response

Beyond the yield point a plastic material strains continuously and

permanently

The plastic material flows but is different from viscous materials

since it has some fundamental strength (the critical stress) which the

viscous fluid does not have

Also, in ideally plastic materials, the strain takes place in localized

regions where the critical stress has been reached, whereas, ideally

viscous materials show deformation throughout the material wherever a

deviatoric stress is present

Elastico-Plastic

Response

As noted above, most materials that display plastic behavior display

elastic behavior below the critical stress

Such materials are said to be elastico ‑plastic

(sometimes called a Prandtl modal) and can be characterized with an analog

model of a spring attached to a sliding mass

The mass requires a critical stress to begin moving against friction,

but a certain amount of elastic strain is sustained by the spring before

the critical stress is reached

Once the mass begins to move (strain) the applied stress has exceeded

the critical stress and a constant stress keeps it moving (straining)

This is an example of a derived response model - one that includes a

combination of one or more of the simple or fundamental models (elastic,

plastic, viscous) in either series or parallel combinations

Derived Response

Models

Most real materials do not respond to stress in a manner exactly like

any of the three elementary responses

In many cases, combinations of these models do approach the behavior of

real rock materials

Other derived response models

Plasticoviscous reponse

Firmoviscous response

Elasticoviscous response

Plasticoviscous

Response (Bingham model)

Analog ‑

dashpot plus a sliding mass in parallel

Visco-Elastic

Response

(Kelvin model)

Also called a firmoviscous response

Analog ‑spring

and dashpot in parallel

The dashpot causes the elastic response to be delayed so that the

elastic (recoverable) part of the response is time dependent both on

loading and unloading

Stress ‑strain

relationship is linear with no fundamental strength for the material

Elasticoviscous

Response (Maxwell model)

Analog ‑

spring plus dashpot in series

Response is instantaneous and strain may increase infinitely

Recovery of the elastic strain is instantaneous, but the viscous strain

is not recovered

|